请与我们联系获取更多信息

询价及技术咨询请添加微信,我们会及时回复

询价及技术咨询请添加微信,我们会及时回复

联系方式

总机: 400-0629-011

手机: 13564748000

邮箱: sale@masoneilangroup.com

地址:上海浦东新区商城路506号32层3207室

总机: 400-0629-011

手机: 13564748000

邮箱: sale@masoneilangroup.com

地址:上海浦东新区商城路506号32层3207室

中文版 English

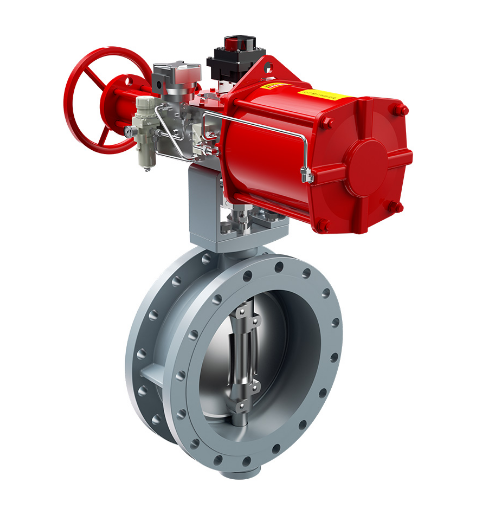

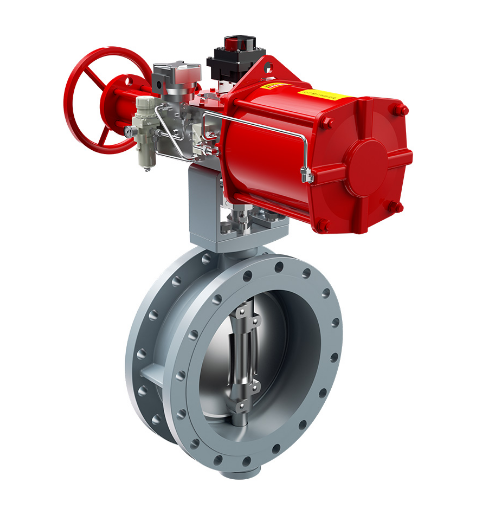

MS670系列三偏心硬密封蝶阀

|

MS670-PDF |

The MS670 series triple offset hard sealing butterfly valve features a dual offset structure combined with an asymmetrical sealing surface design. This design ensures that the valve plate has no friction with the valve seat throughout its entire 0-90° travel range, eliminating wear and friction forces caused by rotation in control valves. It changes the traditional sealing method of rotary control valves that relies on grinding to achieve sealing, and instead uses a compression seal. The valve seat adopts a multi-layer structure, combining metal and special non-metal materials to form the sealing surface, which effectively ensures leak-tightness. This series of butterfly valves offers a long service life, excellent sealing performance, and can meet the requirements of high-temperature applications. It is suitable for regulating and cutting off most gases and liquids in industrial process control.

Technical Specifications:

-

Size Range: 2” to 100” (DN50-DN2500)

-

Pressure Range: ANSI 150-900# (PN10-PN150)

-

Connection Types: Wafer, Flanged, Lug

-

Flow Characteristic: Approximately Equal Percentage

-

Valve Body Type: Straight-through

-

Bonnet Type: Standard Integral

-

Adjustable Ratio: 30:1

-

Standard Leakage Class: CLASS IV

-

Temperature Range: -196°C to 650°C

-

Shaft Sealing: Self-sealing packing structure with flexible graphite packing structure