询价及技术咨询请添加微信,我们会及时回复

询价及技术咨询请添加微信,我们会及时回复

总机: 400-0629-011

手机: 13564748000

邮箱: sale@masoneilangroup.com

地址:上海浦东新区商城路506号32层3207室

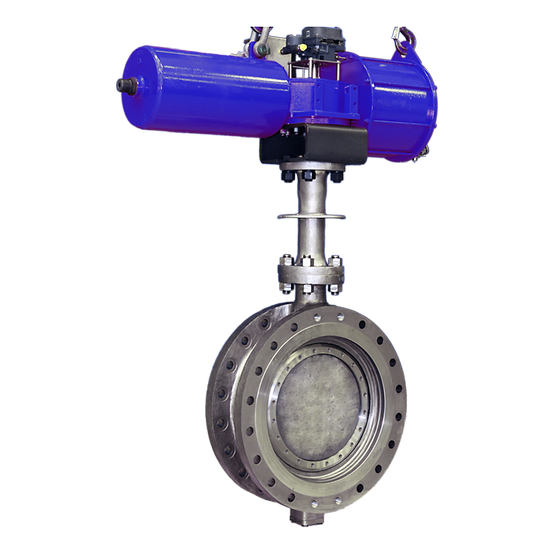

Cryogenic butterfly valve

Features:

Non-rubbing 90-degree rotation and metal-to-metal torque seating provide bi-directional zero leakage tightness to ISO 5208, EN 12266-1 and API 598.

Bolted extended bonnet protects packing from cryogenic service temperatures.

Forged one-piece Nitronic® 50 metal seal ring ensures high corrosion resistance and keeps important mechanical features at low temperatures.

Buttweld top entry design allows access without removing the valve body from the line.

Stellite® grade 21 overlay seats are maintenance-free.

Robust and fire-resistant all-metal construction.

Spot-faced flanges ensure maximum joint-to-pipe integrity.

Robust one-piece shaft designed to transfer/maintain torque efficiently.

Two-piece packing gland and graphite packing minimize external emission risk.

Key secured shaft-to-disc connection for maximum shaft integrity.

Heavy duty bearings withstand high pressure loads and wear.

Braided graphite bearing protectors prevent dirt intrusion, ensuring constant running torque and valve operability.

Specifications:

Sizes DN 80 - 1800 (NPS 3 - 72)

Pressure ratings ASME class 150 - 900; EN PN 10 - 160

Temperature range -254°C to +250°C (-425°F to +482°F)

Design Standards API 609, EN 593; ASME B16.34, EN 12516

Flange Standards ASME B16.5/ASME B16.47; EN 1092-1

Face to face ISO 5752; EN 558; ASME B16.10; API 609

Face to face ISO 5752; EN 558; ASME B16.10; API 609

Buttweld ends ASME B16.25; EN 12627

Buttweld top entry ends Vanessa standard